TL;DR:

Accurate tracking of paintless dent repair (PDR) time is crucial for collision repair shops' efficiency and customer satisfaction. Key factors influencing PDR duration include dent size, depth, complexity of damage, technicians' expertise, paint type, and environmental conditions. Digital tools, offering precise timing, detailed logging, and analytics, have revolutionized traditional manual methods. Best practices involve clear protocols, specialized PDR tools, meticulous recording, and tailored digital systems for real-time updates, data analysis, and reporting, ultimately enhancing operational efficiency, customer service, and quality of PDR services.

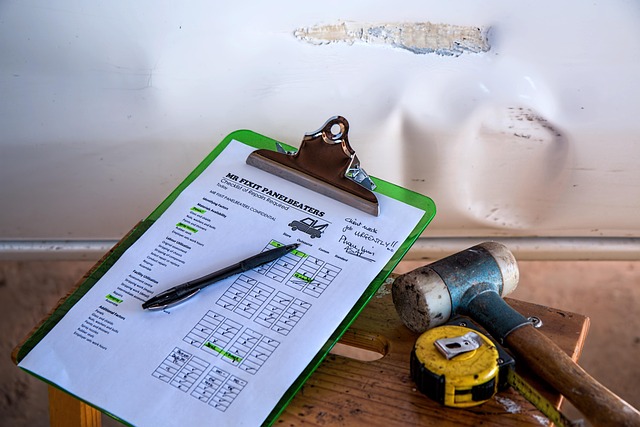

In the fast-paced world of automotive repair, accurately tracking paintless dent repair (PDR) time is crucial for efficient operations and client satisfaction. This comprehensive guide delves into the key factors influencing PDR time, exploring digital tools versus traditional techniques to enhance precision and productivity. We uncover best practices that enable professionals to streamline their processes, ensuring timely and high-quality repairs without compromising aesthetics.

- Understanding Paintless Dent Repair Time: Key Factors to Consider

- Tracking Methods: Digital Tools vs Traditional Techniques

- Best Practices for Accurate and Efficient Paintless Dent Repair Time Tracking

Understanding Paintless Dent Repair Time: Key Factors to Consider

Tracking paintless dent repair time is a nuanced process that requires understanding several key factors. First and foremost, the size and depth of the dent play a significant role; deeper or larger dents typically take more time to repair seamlessly. The complexity of the damage, including any underlying structural issues in the vehicle body, also impacts repair duration.

Additionally, the expertise and experience of the technicians involved are crucial. Skilled professionals can often streamline the process, using specialized tools and techniques to minimize the paintless dent repair time. The type of paint and finish on the affected area, as well as environmental factors like temperature and humidity, further influence the timing. Efficient tracking of these variables ensures that car paint services and vehicle collision repairs are completed promptly, while also maintaining high-quality tire services for optimal customer satisfaction.

Tracking Methods: Digital Tools vs Traditional Techniques

In the realm of paintless dent repair, tracking time is a critical aspect that influences efficiency and profitability. The methods employed to monitor this process have evolved over time, reflecting advancements in technology. On one hand, traditional techniques often rely on manual timing and estimation, which can be subjective and prone to human error. This method typically involves professionals using their expertise and experience to gauge the required time for each repair, sometimes through rough calculations or visual assessments. However, while conventional methods have their place, especially in seasoned workshops, they may not offer the precision and data-driven insights that modern solutions provide.

In contrast, digital tools have emerged as game-changers in tracking paintless dent repair time. These innovative applications and software platforms allow for accurate timing, detailed logging, and comprehensive reporting. With real-time data capture and automated analytics, auto repair services can now gain valuable insights into the efficiency of their processes. This level of precision enables workshops to optimize their techniques, allocate resources effectively, and ultimately enhance customer satisfaction by delivering timely vehicle dent repairs.

Best Practices for Accurate and Efficient Paintless Dent Repair Time Tracking

Accurate tracking of paintless dent repair (PDR) time is essential for maintaining efficiency and customer satisfaction in any collision repair shop or auto body workshop. The best practices involve establishing clear protocols and using specialized tools designed for PDR time management. Each step of the repair process should be meticulously recorded, from initial assessment to final touch-ups, ensuring a comprehensive log that allows for precise calculations. This includes documenting preparation time, which can significantly impact overall completion times, especially for complex car scratch repairs or auto collision repairs.

Implementing digital systems and software tailored for PDR can streamline the tracking process. These tools enable real-time updates, data analysis, and reporting, providing valuable insights into repair times, identifying potential bottlenecks, and allowing for more accurate quoting to customers. By adopting these best practices, a collision repair shop can enhance its operational efficiency, improve customer service through transparent communication of turnaround times, and ultimately, deliver superior quality PDR services.

In conclusion, tracking paintless dent repair time efficiently is paramount for ensuring quality service and optimal shop productivity. By understanding key factors influencing repair duration and employing best practices, technicians can achieve precise timing. Digital tools offer significant advantages over traditional methods, providing real-time data, improved accuracy, and streamlined workflow management. Ultimately, adopting modern tracking techniques allows businesses to enhance customer satisfaction and maintain a competitive edge in the automotive service industry.